Integrating Multivariable Transmitters

with Analog Instrumentation

Steve Oxenberg, Honeywell Inc. Fort Washington, PA.

An interface module recently released for sale by Vektron Corporation has removed many obstacles faced when integrating

digital transmitters with analog instrumentation. Now for the first time, users can mix digital and analog

instrumentation while retaining the key benefits of each.

An interface module recently released for sale by Vektron Corporation has removed many obstacles faced when integrating

digital transmitters with analog instrumentation. Now for the first time, users can mix digital and analog

instrumentation while retaining the key benefits of each.

The module, using Honeywell's

Smart Transmitter

digital communications protocol offers many of the benefits of digital integration for general use with any

manufacturer's analog DCS, PLC, safety shutdown system, critical loop controller, PV trip switch or recorder.

Compatible digital instrumentation can directly utilize the transmitter's accurate PV, status and configuration

database. At the same time, analog instrumentation can utilize the module's 80% accuracy improvement, multivariable PV

access, independent transmitter status and more.

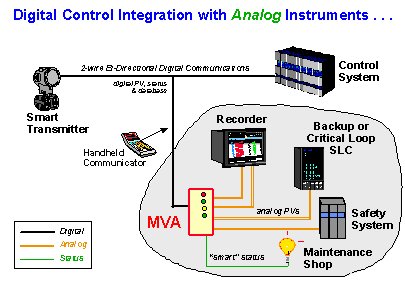

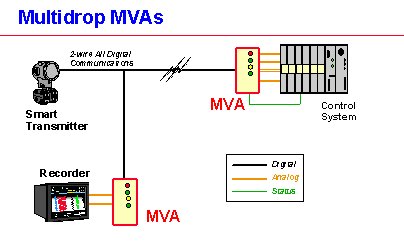

Figure 1 - Expanding with Digital Communications

Figure 1 - Expanding with Digital Communications

The interface module, called the MVA , for Multi-Variable Analog interface, provides

a cost-effective, means of interfacing Honeywell Smartline® Digitally Enhanced (DE) transmitters with analog

instrumentation. The DE communications enable accurate, secure measurements and device diagnostics that protect system

security and integrity. The MVA accepts a digital signal from the transmitter and converts it into four high precision

analog 1-5 volt signals. In addition, the MVA also provides an independent "smart status" relay output whose state is

linked to the digital transmitter's status.

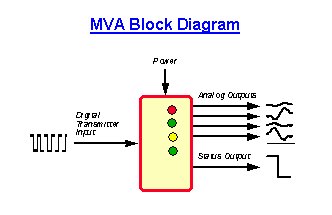

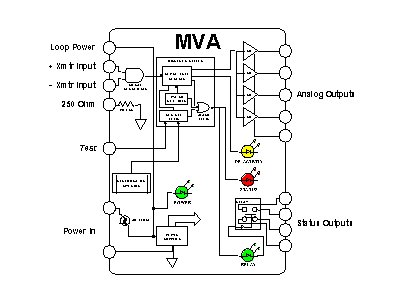

Figure 2 - Multivariable Interface Block Diagram

Figure 2 - Multivariable Interface Block Diagram

The MVA appears to provide a multitude of integration options for integrating digital transmitters with analog products

from other manufacturers. This situation is not unlike those we will face when digital Fieldbus transmitters arrive. As

Vektron explained; "The MVA's flexibility is attributed to a close working relationship with Honeywell."

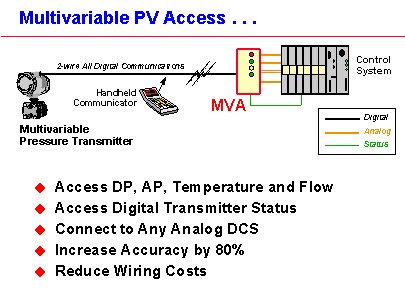

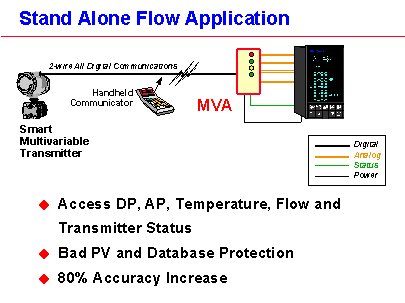

ACCESS TO MORE VARIABLES

Enabling every transmitter to communicate digitally means more measured variables can travel through the same wire

pair. Since the MVA can output up to four analog signals, with a multivariable

SMV3000 Pressure Transmitter

from Honeywell, a user can gain access to all four process variables (PV) or even one of the secondary

variables (SV). This significantly reduces the overall solution cost by not having to install additional

transmitters or new field wiring.

Honeywell now has at least three

multivariable transmitters

on the market; SMV3000 Pressure Transmitter, SGC3000 Gas Chromatograph, and MagneW Plus Flowmeter. Vektron indicated

that the MVA also works with all 3rd party DE field instruments like the multivariable smart level transmitter from

Drexelbrook Engineering Company

. As explained, the MVA was designed as a generic DE interface enabling it to be compatible with any DE transmitter

regardless of who, when or where it was manufactured. This assures both past and future compatibility.

Figure 3 - Accessing Multivariable Transmitters

Figure 3 - Accessing Multivariable Transmitters

Other manufacturers, like

ProSoft Technologies Inc.

, have also developed MVA compatible DE multivariable interfaces for platforms such as the Allen-Bradley PLC-5 and

SLC-5 programmable logic controller series.

The MVA can be used either to enhance an existing installation or, because of the ability to provide loop power, in a

stand alone installation.

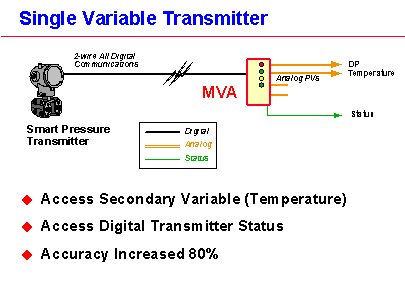

For existing installations, the MVA operates in a high input impedance listener mode and can be connected

without disconnecting or disrupting the existing wiring. Any currently installed single variable transmitter, such as

the Honeywell ST3000 Pressure Transmitter, can be used to access its secondary variable, temperature and transmitter

status.

Figure 4 - Access Secondary Variable and Status

Figure 4 - Access Secondary Variable and Status

Vektron has also provided complete stand-alone capability in the MVA with the ability to provide the transmitter loop

power and 250 ohm loop resistor. The MVA also utilizes a self-resetting electronic fuse that completely protects

the field wiring from short-circuits.

Figure 5 - Stand Alone Digital Transmitters

Figure 5 - Stand Alone Digital Transmitters

IMPROVING ANALOG ACCURACY

A rather unique benefit of the MVA is that it significantly improves the overall measurement accuracy. The MVA was

designed for improved overall performance by incorporating precision voltage outputs instead of traditional current

outputs. This enables installation without the traditional loop resistor and its associated error. Since virtually all

instrumentation actually requires a voltage input, this has the effect of improving the overall accuracy by 80%. That

means that by introducing the MVA into an existing analog loop, better analog performance is obtained from the same

transmitter!

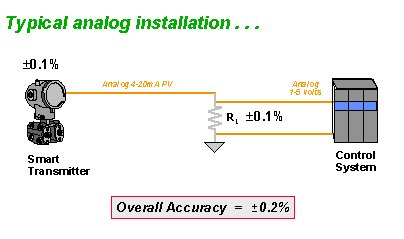

Figure 6 - Typical Analog Accuracy

Figure 6 - Typical Analog Accuracy

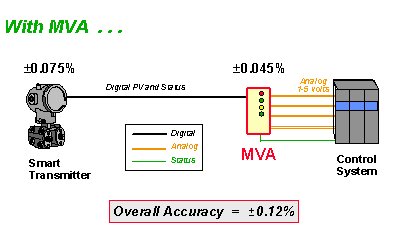

Assuming a typical analog transmitter accuracy of (0.1%, the loop resistor contributes an additional (0.1% inaccuracy

for a worst case error of (0.2%. With the MVA installed, the transmitter's digital accuracy is typically (0.075%. But

since the MVA's outputs are precision (0.045% voltage sources, the error introduced by the loop resistor is eliminated.

The worst case error is now only (0.12%, an improvement of 80%.

Figure 7 - Enhancing Analog Accuracy with MVA

Figure 7 - Enhancing Analog Accuracy with MVA

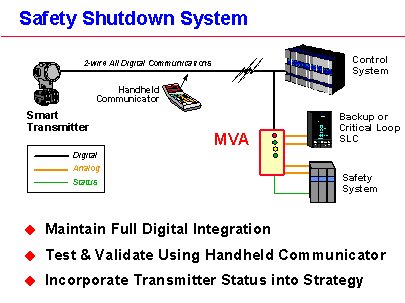

ENHANCING SHUTDOWNS & PERSONNEL SAFETY

Analog instrumentation such as safety shutdown systems, backup or critical loop safety controllers, trip switches, and

recorders can obtain their analog input signal from the MVA. The additional benefits gained through utilization of the

digital field communications are bi-directional communications, improved noise immunity and PV value validity.

Figure 8 - Digital Transmitter in Safety System

Figure 8 - Digital Transmitter in Safety System

Shutdown systems can be configured to respond faster and avoid process upsets or false shutdowns because of the greater

validity associated with digital PV transmission and transmitter status. Furthermore, the independent transmitter

status relay output is useful in differentiating a maintenance problem from a process problem. False

shutdowns may be avoided by incorporating this status differentiation into the shutdown strategy. Vektron also

indicated that the MVA design has taken into consideration the emerging requirements of IEC 1508 for safety

related equipment.

The MVA also has other refined features like user configurable forced "output mode" action. This permits the user to

select whether or not a transmitter's forced output value causes the MVA's "smart status" to trigger a bad status or

pass through as normal. When disabled, this feature may be used to validate safety shutdown operation. When enabled, it

acts as a watchdog, preventing the user from inadvertently leaving a transmitter in a forced state.

Since each of the digital PVs carries its own related status and are separately processed, depending on transmitter

type, the failure of one PV will not effect other PVs. This enables a more reliable trip action based on the

transmitter's predetermination of PV validity.

The analog output fail-safe direction is user configurable to go to burnout high, burnout low or even more useful, hold

the last known good (LKG) PV input value. By utilizing LKG and the "smart status" relay output, the user now has a

simple means of reducing the likelihood of process upsets, false shutdowns and may allow more time to take corrective

action by holding the analog output at its last good value. Unnecessary trips out to the field may be avoided with the

additional visibility of transmitter status. These are sophisticated features found mainly in large distributed control

systems. With features like this, it doesn't take much to recover the MVA investment. MULTIDROP TOO ! Because of its

high input impedance, more than one MVA may be multidropped on a single transmitter with essentially no penalty. This

has the advantage of delivering a precision analog signal with transmitter status anywhere and at virtually any

distance.

Figure 9 - Deliver Analog Signal Anywhere

Figure 9 - Deliver Analog Signal Anywhere

HOW IT WORKS

The entire MVA is configured through simple DIP switches and does not require any special tools or software.

Installation and checkout is simplified with four colored LED indicators. The MVA is a self-contained diagnostic tool

with LEDs indicating power, communication activity and "smart status". It even alerts the user if the analog outputs

are cross-wired or shorted.

Figure 10 - MVA Functional Diagram

Figure 10 - MVA Functional Diagram

The MVA provides two security features found in Honeywell DCSs; Bad PV protection and Bad Database protection. This

means that only validated PVs are passed through and status is only considered good when the transmitter configuration

matches that of the MVA. If a problem exists, the MVA's "smart status" LED provides a visual indication of specifically

what is wrong. For routine validation and maintenance, the MVA provides a TEST terminal that forces all analog outputs

to 3.00 volts, 50%, and trips the status relay. The MVA's life cycle costs are minimal since each module is

factory characterized and does not require any periodic calibration.

For current users of DE compatible instrumentation, the MVA enables every digital transmitter to communicate digitally

regardless of other signal destinations. Having accomplished that, all transmitters can take advantage of centralized

configuration, database security and digital control accuracy.

With Vektron, Honeywell appears to have taken an excellent step towards applying technology to achieve new and unique

solutions, while at the same time fulfilling its promise of providing continued support for the DE protocol and meeting

the needs of open interfaces. Vektron has also indicated that the MVA is only the first of a series of products it

plans to offer. Honeywell users will be glad to know that more flexibility is available for use with the first

industrial digital fieldbus protocol.